ARINO DI DOLO (Venice) – The grinder’s heart is the burr, the mechanical element that influences the grind size and the in-cup result. A less well-known fact is that the vast majority of burrs concealed in grinder-dosers around the world are made by Keber, a company which, for 30 years, has been the benchmark in the international coffee industry for steel burr production.

Here are a few figures to immediately define this jewel of Italian industry which, as of 2019, has been part of Gruppo Cimbali, while remaining an autonomous and independent company.

In 2022, with a turnover of €7.5 million, it had over 100 customers, all leading companies in the industry. There are 30 employees in the 4,000 sq m plant working in 2 shifts and 10 in the offices.

To satisfy its customers’ demand for burrs, Keber produced more than one million pieces in 2022, divided between conical (30%) and flat (70%) burrs, totalling 4,000 per day, of 500 different types made for grinder-dosers, fully automatic machines and vending machines. Customers are 70% in Italy and 30% abroad.

However, the global share is higher because many grinder-dosers produced in Italy are mainly distributed abroad and are fitted with Arino-made burrs.

Keber is a model company that grows every day on the strength of investments amounting to almost 20% of turnover.

Over 100 CNC machines, many of them robotic, are therefore used in the production cycle.

Most of these are state-of-the-art machines, but they are joined by the dozen or so tireless original machines that were self-built in the 1970s by Maestro de Botéga Maurizio Keber when the factory was still known as Bottega.

These machine tools, featuring a bedplate made strictly of cast iron to eliminate vibrations and increase machining precision, are still in perfect working order. Carefully and lovingly maintained.

A burr can cost from €2 to €2,000

Prices? A burr can cost from €2 to €2,000 (the model in special vidia 240 steel) and their teeth can be resharpened up to 10 times in the factory.

Keber opened its doors for the first factory tour explained by Christian Biscontin, operations director at Gruppo Cimbali and managing director of Keber, Andrea Fadel, sales director, and Erika Keber, daughter of the founder, shareholder, board member and head of administration and customer relations. Filippo Mazzoni, Coffee and technology specialist at Gruppo Cimbali, was also present for a series of coffee tastings prepared with different burrs. This visit marked the launch of the new brand and the company website.

There was a discussion about the company’s history and what Keber stands for today. With a new logo that perfectly expresses the brand’s identity, enhancing its historical expertise by contextualising it in the panorama of contemporary excellence.

How custom burrs are created with a tailored approach for each customer

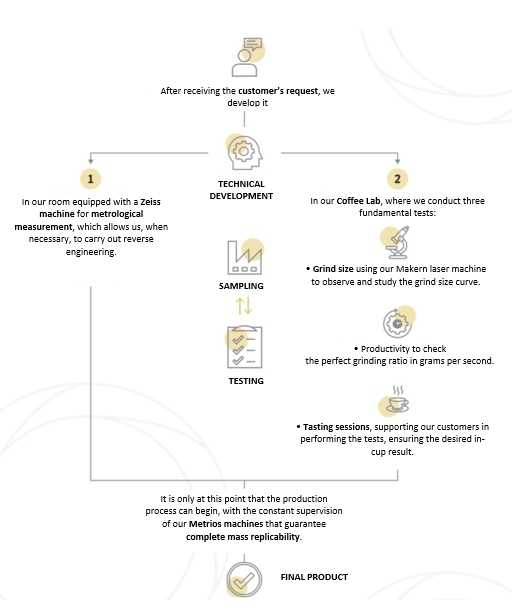

But let’s go into detail to discover how Keber’s specialists design and manufacture burrs tailored to each customer’s requirements. It all starts with the development of new construction techniques and the use of innovative materials, end-of-process heat treatments and coatings to achieve the best quality for products in order to meet customers’ needs with a highly customised approach that Keber describes as ‘tailored’.

Each burr produced is tailored to the specific requirements of each customer, who is involved from the design of the product to mass production. The goal of Keber’s designers is always to know what is needed in terms of productivity and to achieve the perfect espresso every time.

Once the technical specifications and respective drawings have been defined, one or more samples are produced, which then undergo productivity, grind size and extraction tests, involving the customer to agree on the final version.

The selected burr is brought into production (pre-series) and dedicated measuring machines – (three-dimensional, two-dimensional and laser scanner) – guarantee the final product’s repeatability and consistency.

Moreover, thanks to Coffee Lab, it is possible to support the customer in conducting taste tests.

Keber’s burr portfolio is divided into two main segments:

Industrial: referring to grinders used by roasters in their factories

Professional & Prosumer: aimed at manufacturers, spare parts dealers and distributors of grinders, fully automatic machines and vending machines used in the HoReCa sector.

Flat burrs and conical burrs

These in turn are divided into two types, flat burrs and conical burrs. The latter are regaining ground because it has been observed that even with these types of burrs, which reach a maximum diameter of 124 mm, good in-cup results can be achieved.

The choice of which burr to use is determined by the grinder’s construction requirements, as well as the need for a specific productivity level and specific grind size curve. For each sector and type, infinite combinations of material – from basic to premium and stainless steel – of coatings and diameters can be created. Suffice it to say that the company produces over 500 different items each year.

It should be noted that burrs, although a mechanical component, are integrated into a product that results in the preparation of coffee in a cup, and it is precisely the different solutions of materials and coatings that not only enable a longer-lasting product, but also shape the flavour in each cup, consistent with the desired aromatic profile.

At Keber they also take energy saving into account. The photovoltaic system already installed on the plant’s roof is being extended to cover up to 50% of the energy used, while the remainder will come from renewable sources.

Finally, Filippo Mazzoni, coffee and technology specialist at Gruppo Cimbali SpA, Binasco, concluded the day at Keber. Starting with the question “Why do we grind coffee? To increase the contact surface with water,” Mazzoni carried out a series of sensory analysis sessions using different grinders on which new or deliberately worn burrs were installed to show the different results in terms of both grind size and in-cup result.