ACMA, with their brand Tecnomeccanica, dedicated to the development of solutions for packaging tea bags, is today in a position to offer a complete portfolio of machines suited to meet the needs of the main producers worldwide.

The Company, belonging to the Coesia group, designs, manufactures and sells solutions ranging from low to high speed, capable of being configured so as to respond to the most varying packaging necessities.

T4 Modula: flexibility and sustainability as starting point and target

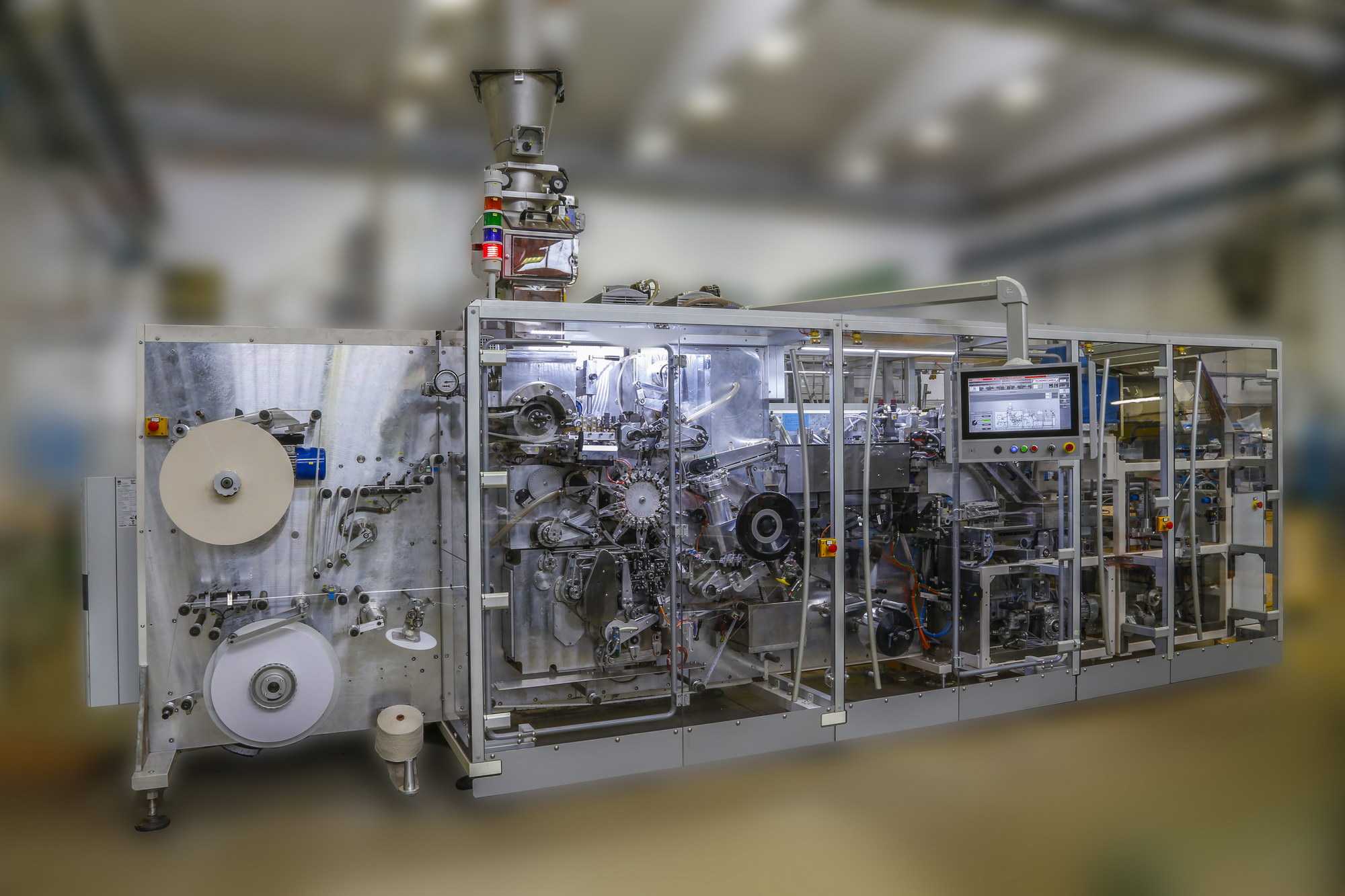

T4 Modula, the solution to manufacture double chamber type bags, has recently undergone a technological upgrade process that enhanced its performance levels, and can today reach a speed of 300 strokes per minute.

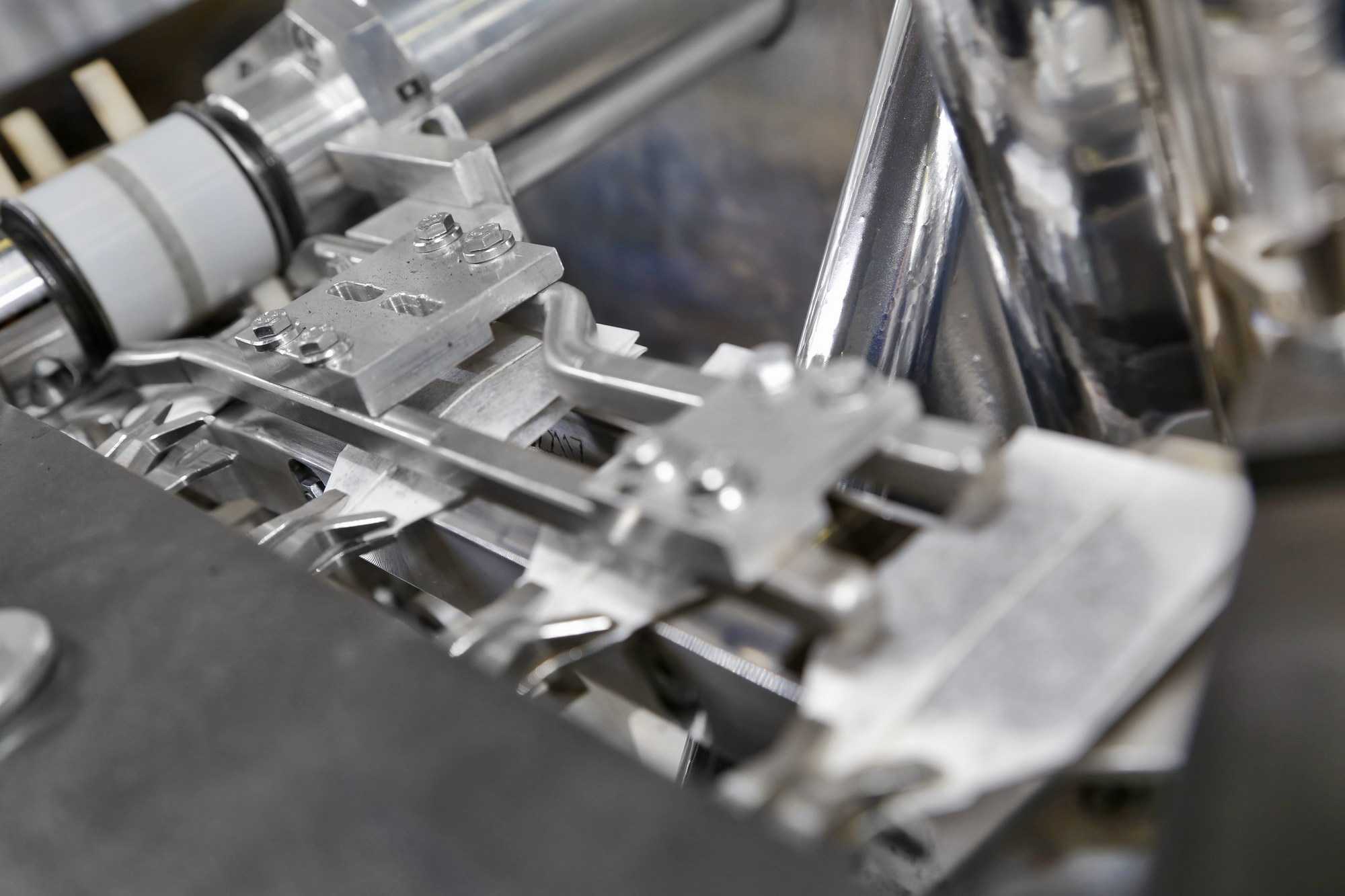

But the characteristics that made it a unique solution in the entire market remain unchanged: the capability of manufacturing double chamber type bags without using glue or staples, with the knotted tag arranged on the front package side, resulting in pleasant appearance and friendly usability.

Besides being particularly attractive, the solution with a knot and without any glue sealing is definitely a top level as concerns hygiene and respect for the environment.

Moreover, the bags can be made from completely recyclable and compostable paper. The T4 is also equipped with sophisticated energy-recovering motors to complete a project that was born taking into highest consideration any aspect tied to environment sustainability and saving.

Finally, the T4 is an extremely flexible machine, capable of being configured so as to respond to the most varying packaging necessities. Moreover, besides handling tea leaves, the machine can also include units to insert bags into cardboard boxes with different sizes and shapes.

A machine line-up for all the markets

The T4 met with great success on Asian markets, especially in South East Asia, as well as in continental Europe. The machine flexibility and modularity make the project suitable for the world-wide market, responding to the needs of manufacturers with different dimensions (and requirements).

Even a quick glance at the entire line-up of Tecnomeccanica makes it evident that the machines of the Italian company are able to cover the most heterogeneous production requirements.

The portfolio also includes the T10 Continua, a top range machine for the packaging of double chamber bags, characterized by continuous movements and capable of reaching 500 strokes per minute.

Manufacturers who face the challenges of single chamber packaging can take advantage of the T2, configurable in various versions, from “Prima” – the basic version – to “Full Leaf” for handling entire tea leaves, up to the “High Speed”, a unit capable of handling up to 320 pieces per minute, that enabled the top players of the sector to greatly save on manpower and to highly enhance production efficiency.

The T2 perfectly responds to the necessities of those companies that increasingly wish to obtain “more with less”, to the extent that over the years it has become one of the most popular machines on the world market.

In comparison to a double chamber solution, theT2 does the job with 40% savings in wrapping material, but involves a limited investment, with at the same time no compromise as concerns the quality of the bag, which, on the contrary, is meeting with increasing favor in the Gourmet, Horeca and Nutriceutical sectors.

PC-based and ARA technologies: simple solutions for complex systems

The T4, as all the machines to be developed and manufactured by ACMA from now on, will be equipped with control systems developed with “PC-based” technology.

In fact, having discarded the PLC platform, all the control components and software for the machine functions will be based on industrial PC’s. PC-based technologies are not only the most effective to monitor the successful machine operation, but also permit constant upgrade processes, that can be run quickly, so as to promptly integrate hardware and software components resulting from future technological developments.

Moreover, they are particularly flexible and easily modified, according to the sectors where they are implemented.

A further advantage deriving from the introduction of PC based platforms is the standardization of functions and components: the new control system is the same for all the ACMA machines, making it simpler to operate on the entire machine park, to implement new functions and to run check and maintenance operations.

To complete this, all the machines of the Company are today equipped with ARA (Advanced Remote Assistance), a system for remote assistance by specialized technicians through a simple LAN connection.

ACMA will be present at Tea & Coffee World Cup in Krakow, Poland, from May 10th through 12th 2016, at stand 528.