Share your coffee stories with us by writing to info@comunicaffe.com.

MILAN – Single-serve capsules are still a market with potential for further development: some insist on aluminum, others are exploring fully compostable materials, while others are moving toward yet another option. This is the case with b-capsules (made by single-layer aluminium Al 8011, laser-sealed, similar to that used in Nespresso Vertuo systems), a new generation of capsule systems for whole beans: we spoke to Bertold Igel, founder of b-Capsule Coffee Solutions.

The b-Capsule concept stands between standard capsule systems and bean-to-cup machines. Who is the product designed for?

“b-Capsule is created for the premium HoReCa segment and office coffee environments, where customers expect bean-to-cup quality but require hygiene, consistency, and operational simplicity.

At the same time, the system is designed for coffee roasters who want to offer their beans in a clean, portioned, and recyclable format — without losing the identity and aroma of their roast.

In parallel, we are exploring a compact home version of a capsule-based bean-to-cup machine, featuring the full cycle: capsule insertion → automatic opening → bean release into the grinder → empty capsule disposal → grinding → espresso extraction → coffee puck ejection.

Optionally, it can include a milk module for cappuccino or latte preparation — keeping the same philosophy: whole-bean coffee, with the convenience and cleanliness of a capsule system.”

Isn’t a system that’s incompatible with others at risk of becoming too niche?

“Every real innovation starts as a niche. Capsule systems themselves were once seen as risky. Our approach is deliberately open and collaborative: we invite roasters, machine manufacturers, and integrators to adapt their systems to the b-Capsule format.

The goal is not to close an ecosystem but to create a new open standard — sustainable, transparent, and technology-driven.”

How much coffee can each capsule hold, and what is it made of?

“Each b-Capsule contains 7–9 grams of roasted whole beans, depending on the roast profile and density. The capsule body is made from a lightweight, recyclable mono-material — we are currently testing both aluminum and biopolymer versions, compatible with existing industrial recycling streams.

The geometry is optimized to protect the aroma and ensure reliable portioning during automated handling.”

Why use whole beans for a format usually associated with ground coffee?

“Because grinding just before extraction is the only way to achieve true freshness. Most capsule systems rely on pre-ground coffee, which loses its volatile compounds within hours.

By sealing whole beans instead, b-Capsule preserves the aroma and essential oils until the very moment of brewing, combining the convenience of a capsule with the quality of a freshly ground espresso.”

Is this choice directly linked to the quality of the coffee being used?

“Absolutely. The b-Capsule format allows roasters to showcase their craftsmanship without compromise — from single origins to microlots. The capsule becomes a transparent carrier of quality, not a limitation. What ends up in the cup truly reflects the bean and roast chosen by the roaster.”

How does the system actually work — how do you get from whole beans to a single-serve cup?

“Inside the machine, the capsule is automatically opened, and the beans are released into a precision grinder. The coffee is then ground and extracted — just like in a bean-to-cup system, but without hoppers, cleaning cycles, or risk of cross-contamination.

The capsule remains dry and empty after use, ready for recycling.”

Does the machine include a built-in grinder?

“Yes. The system integrates a compact, high-precision grinding unit that activates only during extraction.

The mechanical interface ensures the safe opening of the capsule and precise dosing of beans. From that moment, the process is fully automated — ensuring clean operation, traceability, and professional-grade brewing.”

Autonomous cleanliness: after brewing, the capsule remains dry and ready for recycling. How is it disposed of?

“Because no water or waste remains inside, the capsule is completely dry and recyclable. There is no need to separate coffee grounds — they are already extracted.

Both the aluminum and biopolymer versions can be discarded in existing recycling streams for metals or bioplastics. This eliminates the common problem of wet coffee capsules and simplifies post-use handling dramatically.”

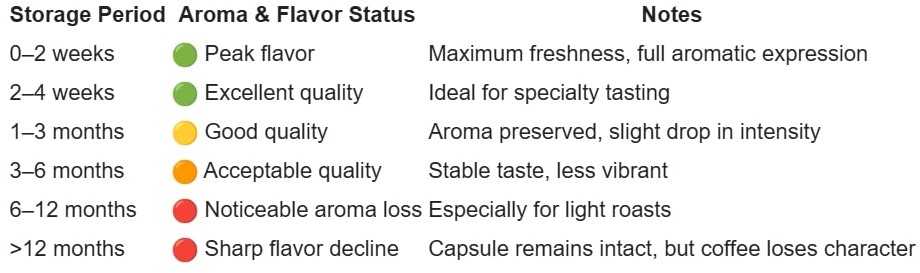

Shelf life and “filled on demand”

“Aroma and Flavor Degradation in Nitrogen-Flushed Capsules wirh whole beans”

All these advantages come at a cost. How much do the capsules and machines cost for end users?

“We are currently finalizing pilot production and integration with equipment partners. The target capsule price will be comparable to premium Nespresso® Professional lines, while machine pricing will vary — from compact office units to high-capacity systems for HoReCa.

Our goal is price parity with bean-to-cup systems, while offering higher hygiene and product flexibility.”

Where and in which markets will the product be available?

“We are preparing pilot installations in Germany, Switzerland, and Italy, in collaboration with local roasters and technology partners. Wider commercial availability is planned for 2026, following certification and the official launch under the b-Capsule Coffee Solutions brand.”