BARCELONA, Spain – VOLPAK, the leading brand in horizontal FFS pouching machines, will be present at the Interpack, Düsseldorf Messe, from May 4th to May 10th, introducing its latest developments and technologies for the pouching market.

The new SI look and innovations with the SI-440, one of the most flexible and versatile horizontal machines in the market today, perfectly adaptable for every need: from projects requiring the large production of small and medium-sized formats to batches requiring large sized pouches.

ENFLEX, VOLPAK’s brand specialized in the design and manufacturing of robust entry-level horizontal pouching machines, will be represented as well, with two models on show.

The F-14 Duplex pouching machine for towelette packaging – a sector where ENFLEX has an established leadership – featuring the simultaneous production of two sachets and the STD-14, the most competitive horizontal Stand Up pouch machine on the market, specifically set up for viscous liquid products.

As always, VOLPAK staff will be your disposal to show the advantages of our flexible pouching solutions.

Stand cap pouch – a win win solution for both producer and consumer

Stand cap pouch – a win win solution for both producer and consumer

In addition to the presented machines, a specific focus will be dedicated to the newly launched Stand cap pouch solution: one of the most attractive and convenient packaging style in the market.

On one hand, the Stand cap pouch allows great savings in packaging costs, since it’s produced from a single reel of flexible packaging material, offering at the same time an excellent product protection and a sustainability claim due due to its low material weight.

Such packaging is key to support a product differentiation marketing and communication strategy, since its shape allows different brands to better display their brand and messages.

On the other hand, the Stand cap pouch provides many advantages for the consumer too, being pleasant to the touch, convenient to consume and empty with a perfect control of the product flow through a flexible valve, it guarantees a minimum volume of waste and, consequently, it’s very easy to be disposed of.

The stand cap pouch is also easy to open and reclose due to its stand up cap. Volpak can provide different models suitable for the manufacturing of stand cap pouches with different filling technologies and hygienic executions, such as hot fill, clean, ultraclean or extended shelf life.

The wide range of configurations makes it possible to use the Volpak machine to package such products as Dairy creams, Condensed milk, Chocolate cream, Marmalade, Cake decorating paste, Honey, Mayonnaise, Ketchup, Tomato paste, Salad dressings, Sauces, Oil, Fats, Conditioner, Shampoo, Gel, Soap, Softener, Fabric cleaner.

The machines on show

The machines on show

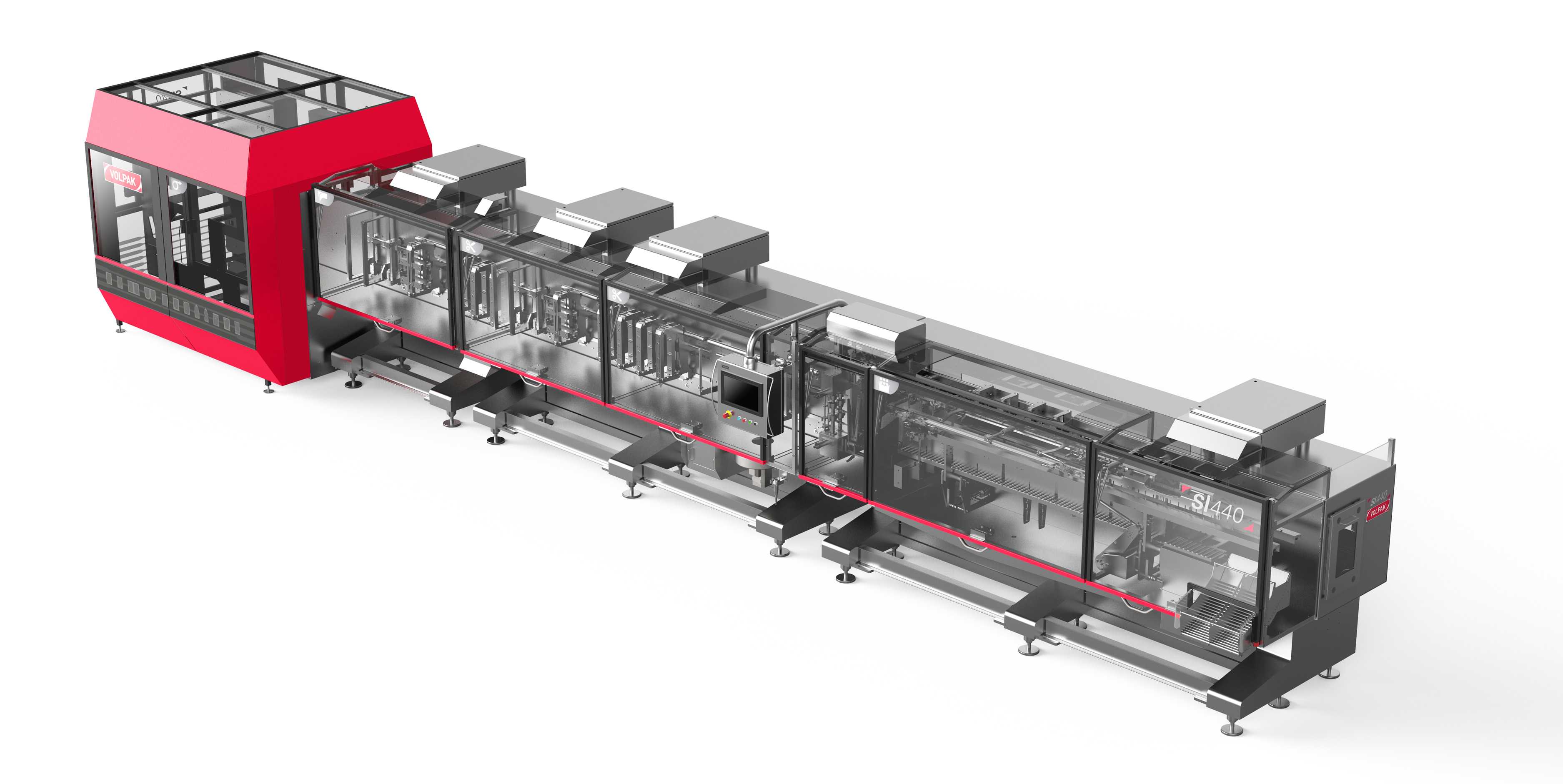

VOLPAK SI440

The new SI-440 horizontal pouching machine (PICTURE) is the result of the company’s intense R&D work and incorporates multiple innovations in electronics, controls, etc.. aiming to be one of the most flexible and versatile horizontal machines in the packaging market today. The SI-440 perfectly adapts to various needs: from projects requiring a large production of small and medium-sized formats (from ¼ litre with production up to 200/spm), to projects that require large format packaging (up to 2 litres, liquid or solid products).

Among the multiple applications for which the new SI-440 model can be used, the cereal market is especially noteworthy, since it is probably the greatest exponent of innovation and modernisation in the packaging market. The zip-close stand-up packaging is the one that best adapts to market tendencies, since it perfectly meets the expectations of both manufacturer and consumer.

Enflex SDT-14

In the making of this machine, the engineers of ENFLEX followed two basic objectives: simplicity and total operation guarantee. The result is the STD-14, the most competitive and widely accepted entry-level horizontal Stand Up pouch machine on the market. It is a machine especially created for the Cosmetic, Food and Chemical industries.

The STD-14 has an unquestionable flexibility that allows it to also manufacture Stand Up pouches with special shapes, zipper closing systems or fitments. The STD-14 has been specially designed for applications of liquids, juices, isotonic beverages, yoghourts, etc.

ENFLEX F-14 Duplex

The F-14 and F-17 models complete ENFLEX’s range of packing machines for towelette sachets. Each one of these machines counts on two commercial versions: the simplex model that produces one sole sachet per cycle and the duplex model for the simultaneous production of two sachets.

For this line of machines, ENFLEX has developed a packaging process which consists of six phases, whereby the two principal functions are carried out in a simultaneous manner.

The machine handles two reels: one for the weaving of the towelettes and one for the plastic material of the sachet, which will later contain these.

After passing through an unwinder and being extended, cut and folded, the towelettes are introduced into the sachets and impregnated with the chosen liquid (perfume, hydrating cream, disinfectant, etc.) at the moment of the packaging into the sachets, which are subsequently sealed.